SiChain, a leading domestic silicon carbide device research and development enterprise, recently announced the release of its first domestically produced 1200V SiC Mosfet device platform product driven by 15V, filling the gap in domestic 15V driven SiC Mosfet products and bringing domestic SiC power device technology to the international leading level. The first 1200V 75m Ω SiC Mosfet has received bulk orders from leading domestic new energy inverter manufacturers, and a series of specification products under this platform will be launched in the future.

SiChain was founded in March 2021 and is a leading domestic designer and supplier of silicon carbide power devices. At the end of last year, it announced the completion of the first round of financing led by Hillhouse Venture Capital, with hundreds of millions of yuan. The company has an internationally leading R&D team, always aiming at the forefront of international technology, and taking it as its responsibility to provide world-class silicon carbide power chips.

Since its establishment one year ago, the company has developed rapidly in terms of technology and products. Currently, it has broken through the bottleneck of domestic SiC power device design and large-scale manufacturing. In a very short period of time, it has successively developed independent intellectual property rights SiC diodes and Mosfet device products. The products have passed vehicle grade reliability tests, and it is currently the only domestic enterprise that can reach the international first-class level in SiC device core performance and reliability, and mass produce SiC Mosfet based on domestic production lines.

Since China clarified its dual carbon targets, the country's new energy industry has entered a stage of leapfrog development. The new energy vehicle industry is entering a period of explosive growth, which has also given rise to a huge market for power devices. SiC power devices, benefiting from their unique advantages of high voltage, high temperature, and high frequency, are becoming the core components of the new generation of power conversion. They have been widely used in fields such as new energy vehicles, photovoltaic inverters, and energy storage, significantly improving power conversion efficiency. The national "14th Five Year Plan" specifically calls for the development of "wide bandgap semiconductors such as silicon carbide", hoping that domestic manufacturers can catch up with international standards as soon as possible and launch independently controllable products.

SiC Mosfet, as the most widely used silicon carbide power device, has long been widely used in flagship product series of leading domestic companies such as BYD, Sunac, and Huawei, and its demand is rapidly expanding. However, the core technology related to SiC Mosfet has never been broken through, and there is still a significant gap in product performance and reliability compared to mainstream international products. The domestic market is mainly occupied by foreign manufacturers.

This device mainly has two types: 18V drive and 15V drive, among which the advantage of 15V drive products is more obvious: customers use 15V drive products, firstly, the system can be better compatible with current IGBT drive circuits; Secondly, it further enhances the reliability of the device while reducing driving losses; Thirdly, most domestic driver chip manufacturers supply 15V driver chips, making it easy to match domestically. However, the development of products driven by 15V is more difficult, with higher requirements for product design level and manufacturing process. After years of efforts, some domestic manufacturers have been able to provide a small amount of SiC Mosfet products driven by 18V. However, mainstream international manufacturers have begun to vigorously promote SiC Mosfet driven by 15V, accelerating the replacement of traditional silicon-based IGBT (Insulated Gate Bipolar Transistor) products and further widening the technological gap with domestic products.

The 1200V SiC Mosfet device platform product driven by 15V released by SiChain fills the gap of this series of products in China for the first time, leading the domestic SiC power device technology to the international leading level. Compared to mainstream international products, the 15V driven 1200V SiC Mosfet device product launched by Pure Semiconductor has lower conduction loss, lower thermal resistance, lower switching loss, smaller overall loss, and higher efficiency.

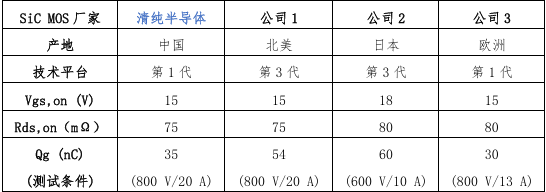

The following table compares pure semiconductor Mosfet with world-class products (derived from the specifications of each product):

The domestically produced 1200V SiC Mosfet series products developed by SiChain based on independent processes have received a warm response from the market since their launch. The first 1200V 75m Ω SiC Mosfet product has passed automotive grade testing and obtained bulk orders from leading domestic new energy inverter manufacturers.

At present, SiChain has completed the productization of the entire series of 1200V silicon carbide power devices, providing specifications such as 1200V 15A, 20A, 30A, 40A SiC SBD (silicon carbide Schottky diode) and 1200V 75m Ω, 60m Ω, 40m Ω, 32m Ω SiC Mosfet (18V and 15V driver options). The SiC devices it supplies have excellent performance at the international advanced level and can be widely used in new energy vehicles, charging stations, industrial power sources, photovoltaic inverters UPS、 In high-power, high-frequency, and high-efficiency fields such as communication power supplies, domestic substitution of SiC devices can be directly achieved, while having advantages such as high reliability and compatibility with IGBT driving voltage. The rich product series can meet the needs of many target applications, further promoting the development and application of domestic high-performance power chips.